Automotive Testing Device

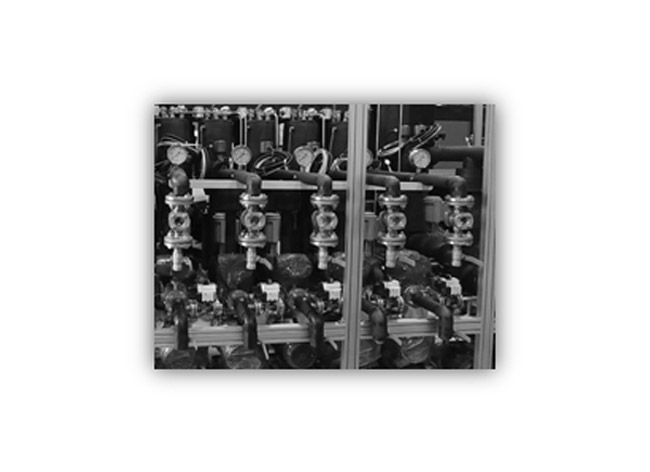

Engine Coolant Temperature Conditioning Device

SPECIFICATION

- Water pump capacity : 2.2 kW(3HP)

- Heating capacity : 2.2 kW(3HP)

- Cooling capacity : 150, 350 kW

- Medium : water-EG mixture

- Operating temperature : 20~120 ℃

- Coolant control temperature : 70~120 ℃

- System pressure : 6 bar

- Circulation volume : max. 60 m3/h

- Main power input : 3P 380V 40A

- Dimension : 900(W) X 700(D) X 2050(H) – 350kW model

- Weight : about 400 kg (water empty) – 350kW model

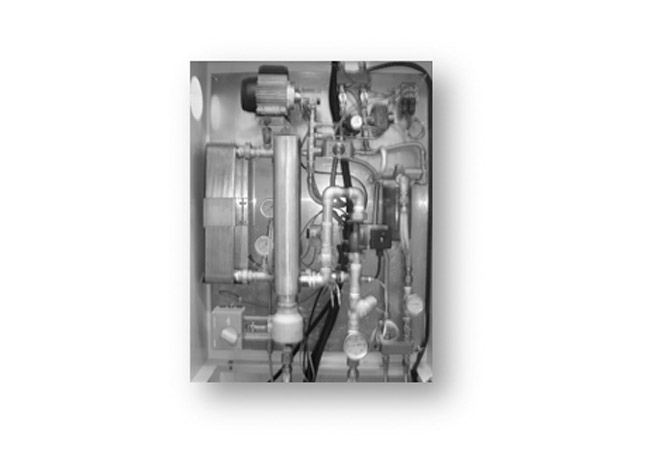

Engine/ATF Oil Temperature Conditioning Device

SPECIFICATION

- Oil pump capacity : 0.75 kW(1HP) or Customer specific

- Heating capacity : 10 kW

- Operating temperature : 20~150 ℃

- Oil control temperature : 70~150 ℃

- Remote set value input : 0~10 V

- System pressure : 10 bar

- Circulation volume : max. 20 L/min

- Main power input : 3P 380V 40A

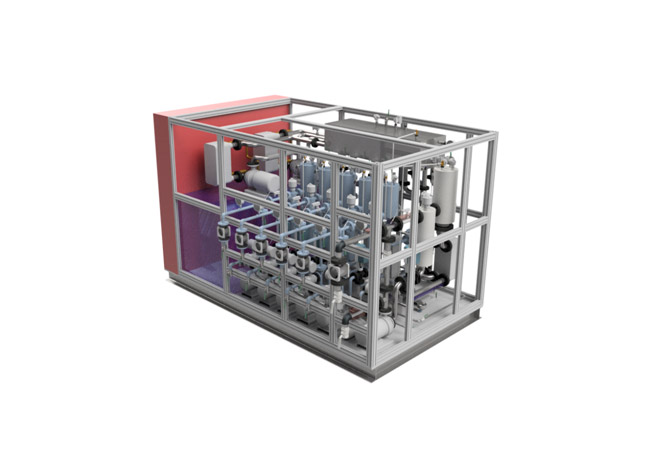

UUT Universal Conditioning System

SPECIFICATION

- Universal Conditioning System for UUT

- All 6 in 1 system

- Engine coolant temperature control

- Motor/inverter coolant temperature control

- High-voltage battery coolant temperature control

- ATF warmer coolant temperature control

- Intercooler coolant temperature control

- Engine intake air Temperature control

Fuel Temperature Conditioning Device

SPECIFICATION

- Fuel pump capacity : 240 W

- Water pump capacity : 350 W

- Heating capacity : 1.6 kW

- Fuel feed temperature : 10~30 ℃

- Fuel control temperature : 10~80 ℃

- Remote set value input : 0~10 V

- Fuel delivery volume : max. 4 m3/h

- Main power input : 220V 15A

- Dimension : 890(W) X 400(D) X 1500(H)

- Weight : 50 kg (water/fuel empty)

Intercooler Temperature Conditioning Device

SPECIFICATION

- Spray type intercooler cooling

- Required supply water pressure : 3~10 bar

- Spray water flow rate : 200 L/min (at 5 bar)

- Inlet/outlet piping size : 25A/50A

- Main power input : 3P 220V 0.5A

- Dimension : depended on intercooler size

Fuel Mass Flow meter

SPECIFICATION

- Fuel mass flow : 0~320kg/h (Specified by customer)

- Accuracy : ±0.2%

- Nominal Pressure : 0.2~0.8 bar (Recommend 05. bar)

- Nominal Temperature : 5~50℃ (Recommend 25 ℃)

- Diesel & Gasoline

- Tube : SUS316 10mm

- Dimension : 700(W) X 400(D) X 800(H)

- Construction : IP65

- Interface : Pulse, Current, HART

- Operation unit: 3.8” TFT LCD touch panel

- Main power input : 220V 60Hz 6A

Fuel Pressure Module

SPECIFICATION

- Vane pump type

- Flow rate : max. 8.4 l/m , 14kg/cm2

- Pressure range : 0~10 bar

- 220V 3ph / 0.3kW

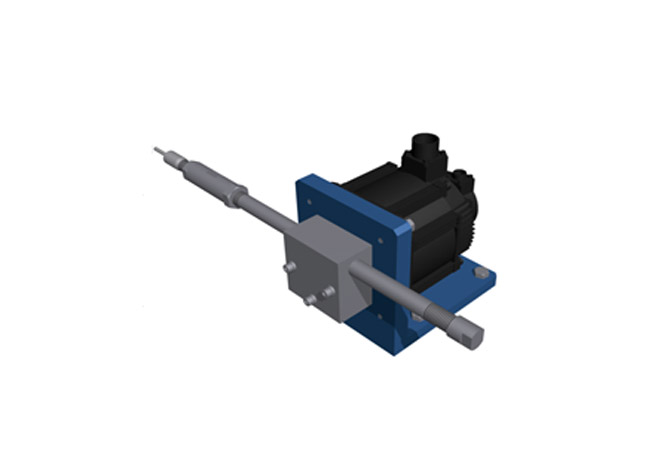

Throttle Actuator

SPECIFICATION

- Max. stroke : 100~150 mm

- Rating shifting force : 120 N (max. 335 N)

- Rating speed : 5 m/s (max. 7 m/s)

- Servo motor capacity : 750W

- Admission range : -20~50 ℃

- Analog input : +/- 10V

- Analog output : +/- 10V

- Weight : 15 kg

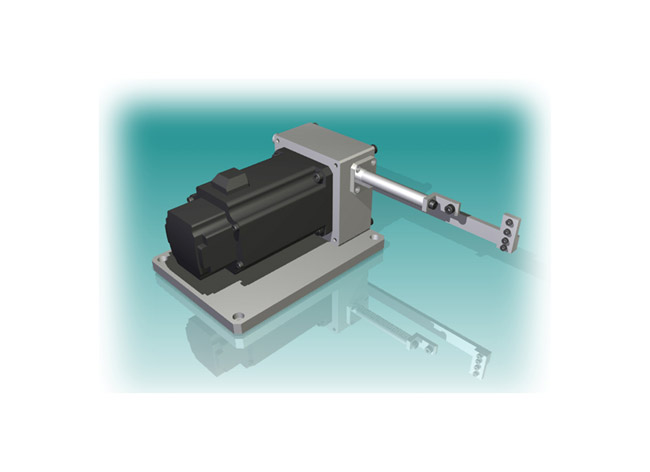

Torque Calibration unit System

SPECIFICATION

- Easy set-up and compact design

- One person operation with no requirements to load weights

- Calibration accuracy of up to 0.05% FSD

- 50% faster time to calibrate due to simply set-up and automated calibration procedure

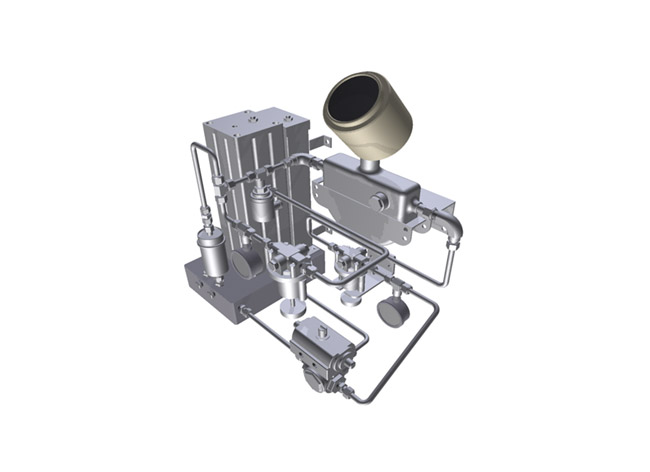

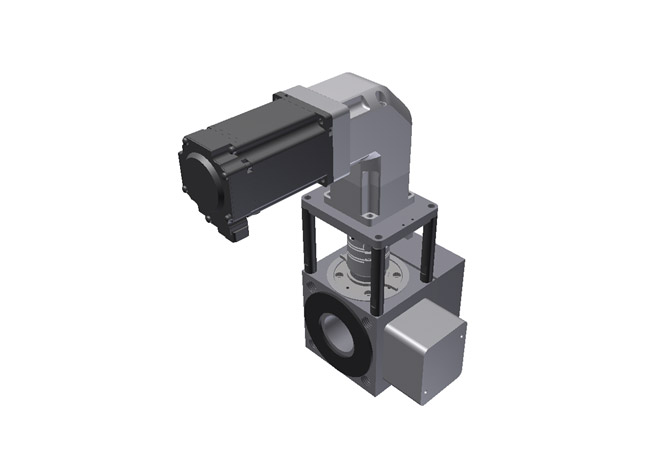

Hydraulic Dynamometer Control Valve

SPECIFICATION

- Butterfly control valve for hydraulic dynamometer

- Inlet and outlet valve control

- Zero/span angle setting

- Analog voltage(0~10V) angle position remote input

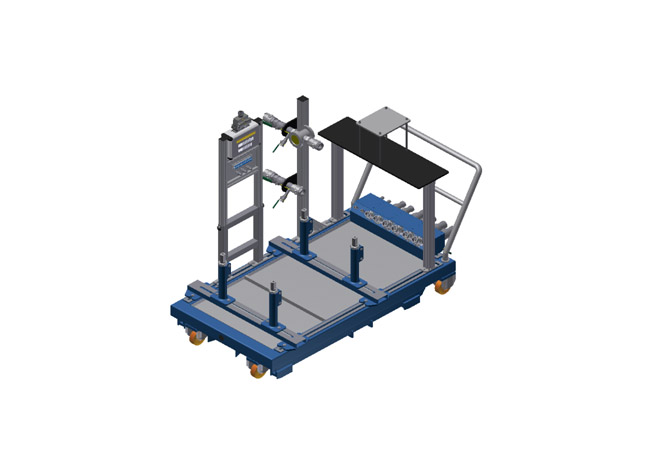

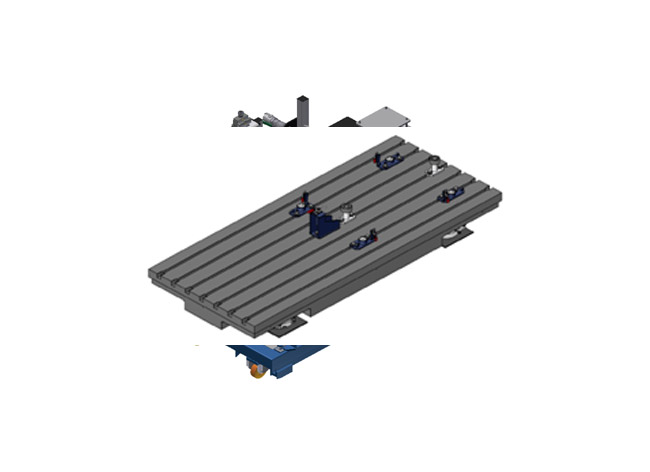

Docking Engine Pallet System

SPECIFICATION

- Media manual-docking system

- Quicker engine installation in the engine test cell

- Pre-setup engine utility line

- Re-use of installed engine with trolley

- Flexible cell operation through alignment between test cells

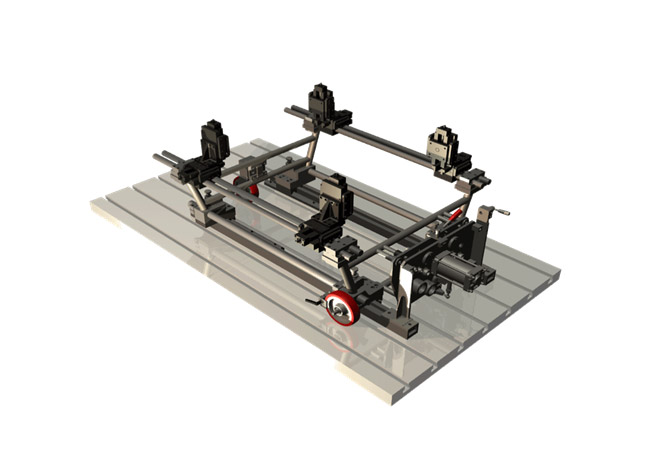

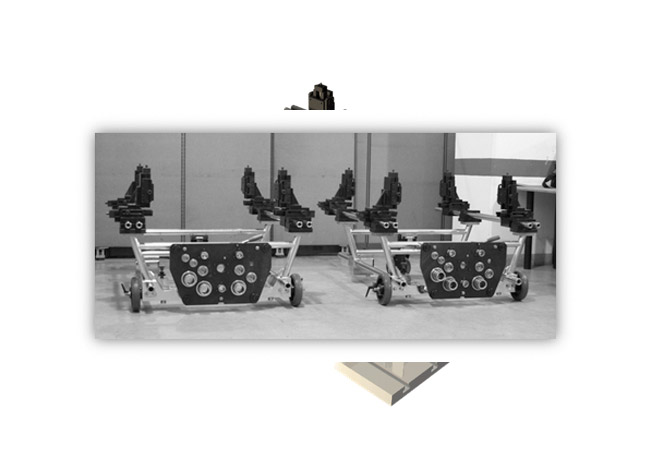

Auto-docking Engine Pallet System

SPECIFICATION

- Media full auto-docking system

- Quicker engine installation in the engine test cell

- Pre-setup engine utility line

- Re-use of installed engine with trolley

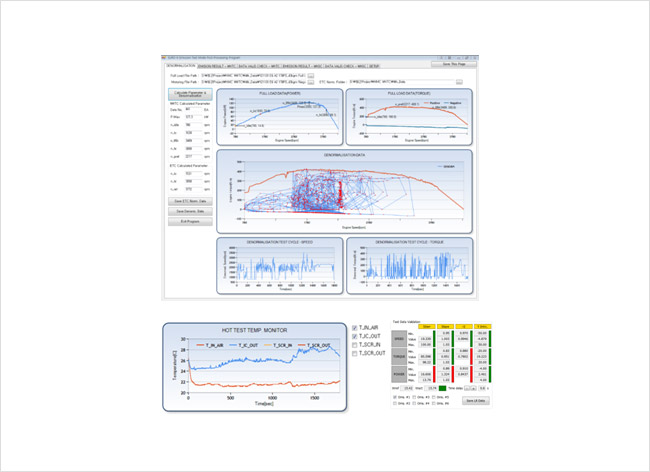

Emission Post-Processing Software

SPECIFICATION

- Pre-/post-processing software for Euro 5(ETC, NRTC), Euro 6(WHTC)

- Engine speed, torque demoralization

- Test data validation

- Validation data text file format(CSV file) saving

- Emission data calculation

- Test report(image file format)

- Test value monitoring tool

DAQ Software for Engine Test

SPECIFICATION

- Engine test automation system

- Fully automatic sequence control

- Various data acquisition function.

- Cost effective system

- Easy to use test sequencing

- Full windows application

- Industry standard hardware

- Modular I/O system

- Interface to existing equipment

- Limits and safety interlocks

Driver’s Aid System Software

SPECIFICATION

- Mode scheduled speed display

- Speed deviation display

- Accumulated distance display

- Shift points display